Modeling & Simulation

Clarity Before Commitment

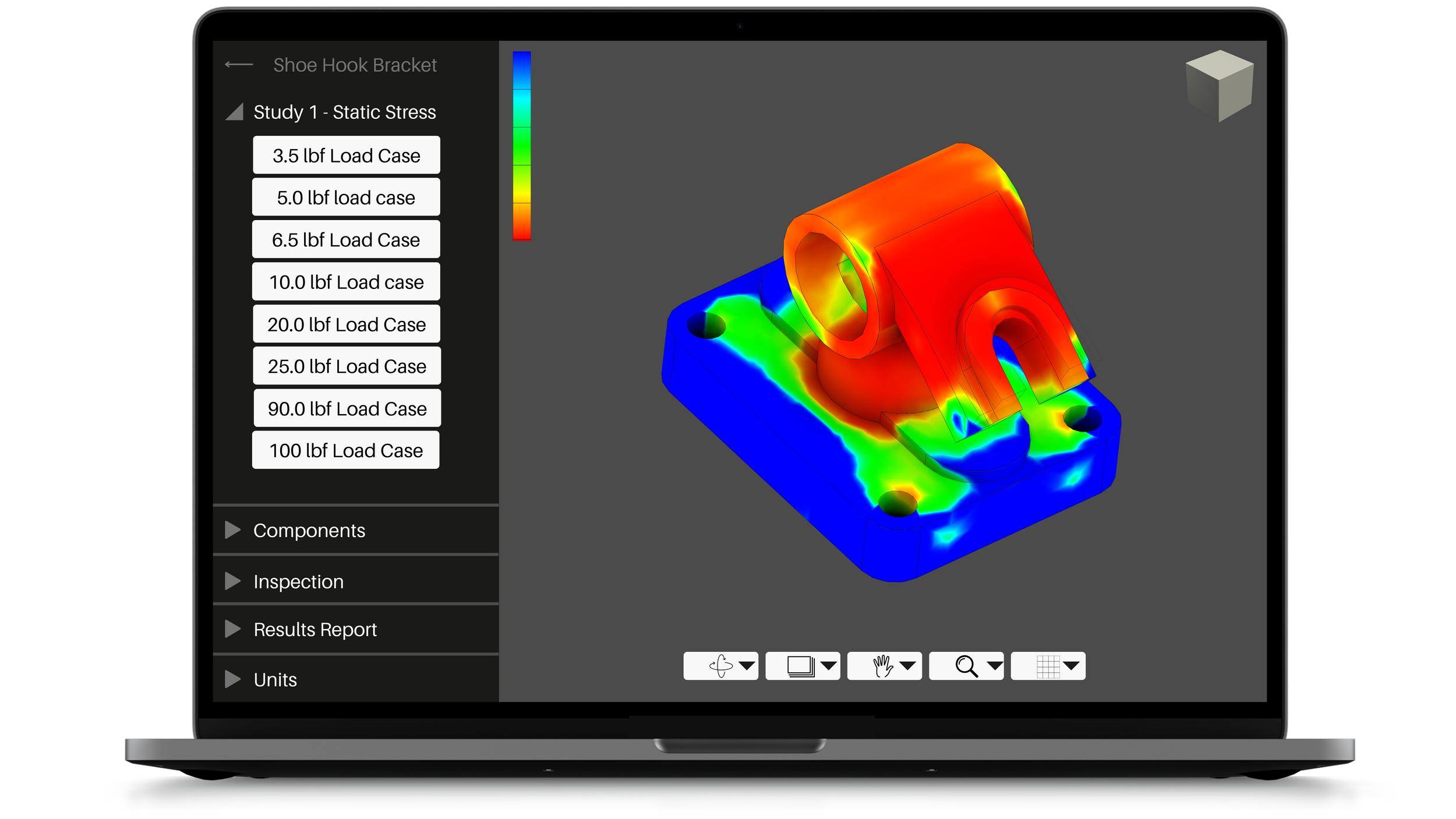

Modeling and simulation create clarity before commitment. By testing performance virtually, we replace assumptions with data and validate decisions before investing in tooling or production. Whether for a stakeholder-driven solution or a consumer product, this approach reduces risk, speeds development, and ensures you move forward with confidence… not guesses.

Predictable Performance

Our modeling and simulation processes evaluate designs for real-world performance, durability, and production readiness. We use static stress analysis to assess strength and deformation under load, modal frequency analysis to prevent resonance and fatigue, and thermal analysis to evaluate heat transfer and efficiency. Combined with a manufacturability review, we ensure each part is high-performing, reliable, and optimized for cost-effective production.